Yangzhou Longxiang Stamping Hardware Co., Ltd.

Yangzhou Longxiang Stamping Hardware Co., Ltd., located in Qiangmin Village, Shatou Town, Yangzhou, is a strong and established enterprise with over 40 years of experience in mechanical processing and metal stamping. With superior product quality, competitive pricing, robust technical expertise, and advanced equipment, our company’s products have earned recognition from industry professionals and enjoy the deep trust of a wide range of customers.

Since its establishment, the company has continuously introduced advanced processing and production equipment and recruited skilled technical personnel. The company’s scale has expanded year by year, and in 2007, it newly expanded its production facility.

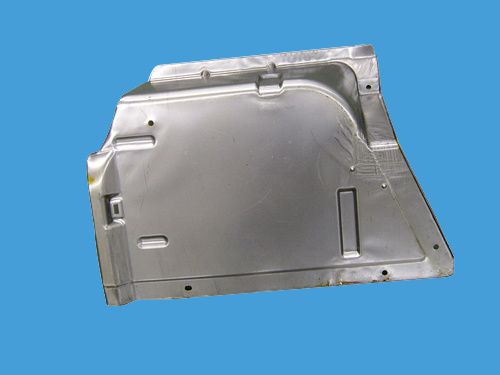

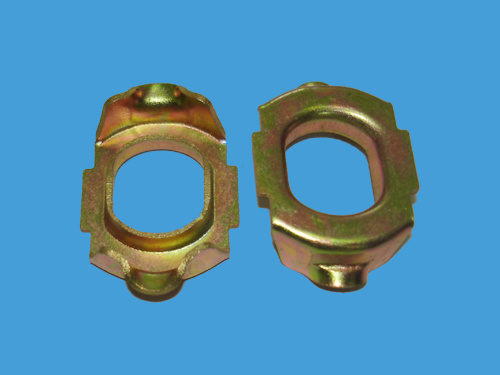

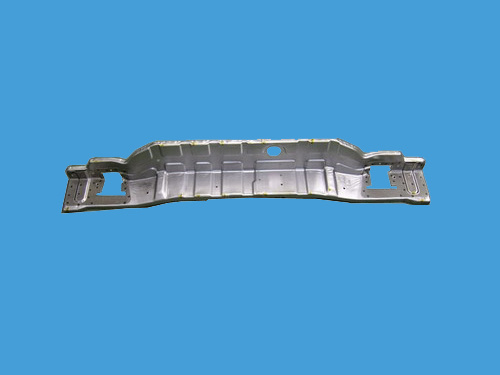

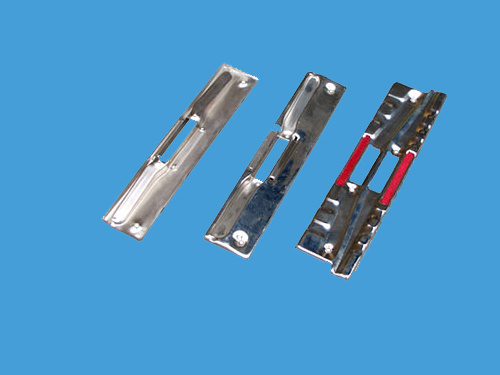

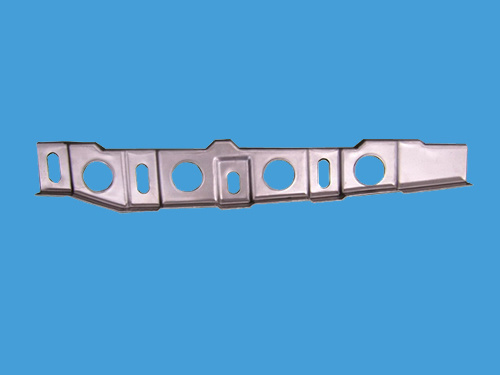

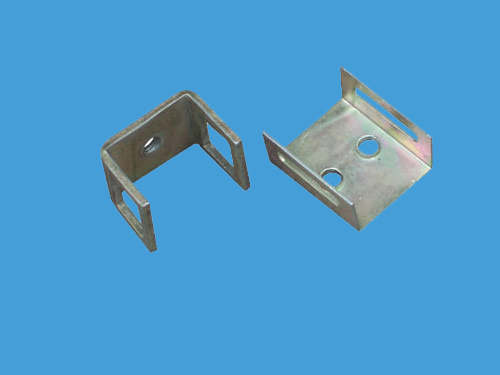

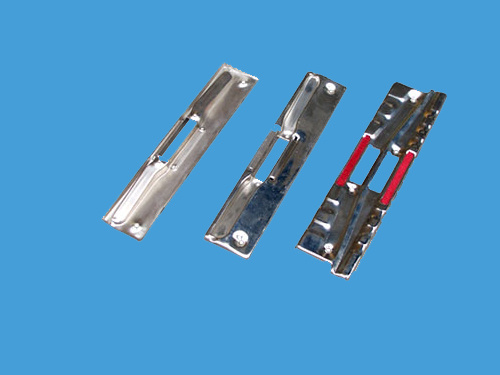

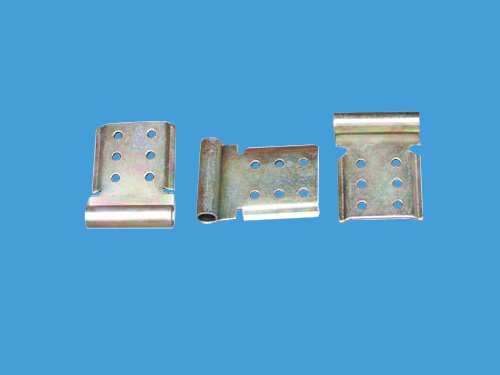

Product Center

A modern manufacturing enterprise that produces various types of wires and cables, as well as a full range of cable connectors and related components.

Core Advantages

A strong enterprise with over 40 years of experience in mechanical processing and metal stamping.

01

Production strength

The company’s scale has been expanding year by year, and in 2007 we newly expanded our production facility. Currently, our factory boasts a professional technical team, 30 stamping machines, and welding robots, making us a modern and specialized manufacturer of stamped products.

02

Product quality

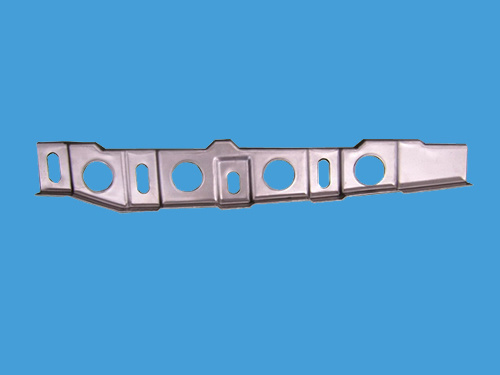

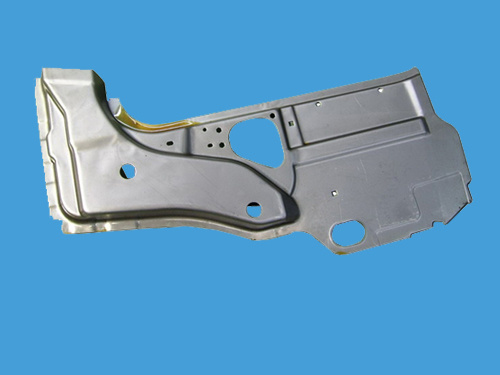

The company has its own R&D team and boasts sophisticated production processes. Its product range includes: primarily stamped parts, hardware components, automotive and motorcycle accessories, welded products, and molds. Thanks to its high quality and diverse offerings, the company has earned unanimous recognition and positive feedback from a wide range of customers.

03

Industrial value

With superior quality, competitive pricing, robust technical expertise, and state-of-the-art equipment, our company’s products have earned recognition from industry professionals and enjoy the strong trust of a wide range of users.

News Updates

Stay promptly informed about the latest news and fresh industry updates.