15

2022-07

Why does stacking occur in automotive sheet metal stamping parts?

1. The main cylinder of the machine tool and the blank holder force are not enough, the forming pressure is too low, and the CAE reference pressure value has not been reached, and the forming pressure needs to be adjusted to solve the problem.

2022-07-15

15

2022-07

Machine vision inspection makes stamping inspection so easy

The advantages of machine vision inspection equipment in the inspection of metal stamping parts: 1. The distance between any circles can be detected; 2. It can detect the distance between the edges of any part; 3. It can detect the center distance, far center distance and near center distance from any edge to the center of the circle; 4. Check whether the stamping product is inclined, missing or bad in size, etc.; 5. Simultaneous implementation of detection, the results can be output through COM, I/O, Internet and other methods; 6. It can store and query detection images; 7. Automatic statistics (good, bad, total, etc.).

2022-07-15

15

2022-07

The solution of necking and pulling cracking of aluminum alloy stamping parts

1. Sheet aging control: The aluminum sheet has the characteristics of aging, with the increase of time, the strength and hardness increase, and the plasticity and toughness decrease. Due to the difference in the sheet metal manufacturing process, the state of delivery after heat treatment, transportation, temperature and other conditions, the mechanical properties of the aluminum sheet before stamping production are very different, which has a great impact on the production adjustment of the mold, and also causes frequent production during continuous production. There are problems such as necking and pulling. In order to solve this problem, we can first accumulate the range of mechanical properties that the mold can produce stably, and then use the aging characteristics of aluminum materials to master the aging rules, and place them out of use for aluminum materials with low yield strength to make them naturally age and increase the yield strength. To the expected range before production. 2. Early warning and interval supply of aluminum sheet mechanical properties By reforming the sheet material card, all the information of the sheet material is printed on the material card, which is convenient for quick comparison and analysis of material properties after production problems occur. In addition, the performance data of production problems are summarized and summarized to form its own performance warning range for each aluminum alloy stamping part. The use of blue card materials beyond the range plays a role in early warning of defects.

2022-07-15

15

2022-07

Talking about the difference between metal stamping dies and plastic processing dies

The difference between metal mold and plastic mold: 1. Hardware molds are stamping parts that are processed by various presses and special tools mounted on the presses in industrial production to process metal materials according to the desired shape of the finished product. Such special tools are collectively referred to as metal molds. 2. Plastic mold A combined plastic mold used for compression molding, extrusion molding, injection molding, blow molding and low-plastic molding, changes in mold convex, concave mold and auxiliary molding systems. It can process a series of plastic parts of different shapes and sizes. 3. From the function of the mold, the metal mold is a mass production tool for metal products. The materials used are generally iron, copper or aluminum. The plastic mold is made of plastic products, and the raw materials used are also plastic raw materials.

2022-07-15

15

2018-06

Analysis of the conditions for precision stamping parts stamping materials

Precision stamping parts are manufactured through a series of stamping processing processes such as stamping, extrusion, rolling, welding, cutting, etc. The manufacturing is more difficult. In order to meet production requirements and achieve good product molding effects, precision stamping parts The stamping materials have higher requirements. So what are the conditions for precision stamping parts stamping materials? The following editor will analyze and answer for you.

2018-06-15

20

2018-06

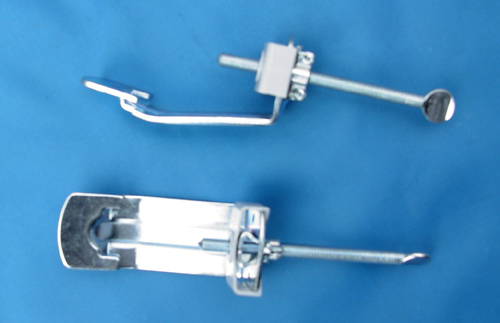

Metal stamping die stamping parts use a flip-chip composite die structure. It is mainly composed of rigid pusher device, elastic discharge device, positioning parts, punching punch, blanking die, convex and concave die, fixed plate and pad plate. The die frame uses the center guide column die frame with smooth sliding, accurate and reliable guidance.

2018-06-20